Винтовые клеммники КВТ серии КЕ10 для СИП

Если посмотреть статистику причин пожаров в жилых домах, можно увидеть, что значительная часть пожаров происходит из-за неисправной электропроводки. И к особой группе риска вполне возможно отнести подключение к уличной сети через провод СИП (Самонесущий Изолированный Провод).

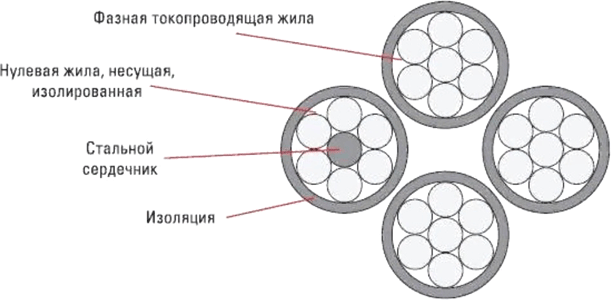

В конструкцию провода СИП входят основные (фазные) жилы, состоящие из алюминия или алюминиевого сплава, и нулевая жила. Нулевой проводник может быть полностью изготовлен из алюминиевого сплава, или иметь внутри стальную сердцевину, покрытую снаружи алюминиевым сплавом. Сразу следует отметить, что провод СИП с медными жилами не выпускается.

Для проводов СИП, впрочем, как и для других видов кабелей и проводов, важнейшим параметром является сопротивление жилы, а не ее сечение. Кроме того, согласно ГОСТ 31946-2012 провода СИП предназначены для воздушных линий передач. Исключение составляют провода с литерой «н». Их можно прокладывать по стенам зданий с внешней стороны, и то на определенном расстоянии от поверхности стены. Естественно, что в таких условиях особое значение приобретает надежность соединений провода СИП с внутренней проводкой.

Винтовые клеммники серии КЕ10 производства Калужского завода КВТ специально изготовлены для решения таких задач, как соединение и разветвление алюминиевых и медных проводников внутри стоек и щитов в опорах и мачтах уличного освещения, а также при монтаже самонесущих изолирующих проводов СИП. Подключение алюминиевого провода СИП напрямую к вводному устройству, мягко говоря, нежелательно. Связано это с тем, что контакты вводных устройств выполнены из меди, или латуни. Как известно, медь (латунь, бронза) и алюминий имеют разные коэффициенты теплового расширения, что может привести к ухудшению контакта, обгоранию провода, оплавлению или возгоранию изоляции провода. При использовании же клеммников КЕ10, каждый провод имеет свой собственный винтовой зажим, что позволяет использовать как медные, так и алюминиевые провода в любых сочетаниях и разного сечения. Кроме того, клеммники КЕ10 имеют на контактной части специальную абразивную пасту, обеспечивающую гарантированный контакт алюминиевых и медных проводов.

Следует иметь в виду, что подключение проводов к клеммнику должно производиться с помощью наконечников. Согласно ГОСТ 10434-82 «разборные контактные соединения многопроволочных жил проводов или кабелей с плоскими и штыревыми выводами должны выполняться…после оконцевания наконечниками».

Клеммники КЕ 10 можно использовать в сетях с рабочим напряжением до 1000В в интервале температур от -60 до +55°C.

При использовании защитного колпачка КНК (только для 4-контакных клеммников) степень защиты такого соединения составляет IP44.

Прозрачный изолирующий корпус обеспечивает визуальный контроль как в процессе монтажа, так и в ходе всего времени эксплуатации. Корпус является неразборным, что гарантирует надежность изоляции контактного соединения. Момент затяжки контактной части составляет 10 Нм.

Основные технические параметры

| Модель | КЕ10.1 | КЕ10.3 | КЕ10.504 | КЕ10.506 |

|---|---|---|---|---|

| Количество контактов | 4 | 6 | 4 | 6 |

| Материал контактной части | алюминиевый сплав | |||

| Материал прижимных болтов | анодированная сталь | |||

| Материал изолирующего корпуса | поликарбонат | |||

| Рабочее напряжение, В | ≤1000 | |||

| Размеры, мм | 61х30х36 | 90х30х36 | 61х30х36 | 90х30х36 |

| Сечение жил (медь), мм² | 1,5-25 | 2,5-25 | ||

| Сечение жил (алюминий), мм² | 10-35 | 10-50 | ||

| Рабочий диапазон температур, °С | -60...+55 | |||