Особенности применения ограничителя пускового тока серий ICL от MEAN WELL

Одним из факторов, который следует учитывать при создании системы электропитания любой нагрузки, является наличие пускового тока, его максимального значения и продолжительности. Пусковой ток, входной импульсный ток или импульсный импульс включения — это максимальный мгновенный входной ток, потребляемый электрическим устройством при первом включении. Электродвигатели переменного тока и трансформаторы могут потреблять в несколько раз больше обычного тока полной нагрузки при первом включении питания в течение нескольких циклов входного напряжения. Силовые преобразователи также часто имеют пусковые токи, намного превышающие их номинальные токи, из-за тока заряда емкости входного фильтра.

Выбор устройств защиты от перегрузки по току, таких как предохранители и автоматические выключатели, усложняется, когда необходимо допускать высокие пусковые токи. Защита от перегрузки по току должна быстро реагировать на перегрузку или короткое замыкание, но не должна прерывать цепь при протекании (обычно безвредного) пускового тока. Поэтому для ряда применений целесообразно применение ограничителей пускового тока. Однако при выборе ограничителя важно понимать его устройство и назначение для применения, чтобы он выполнял свою функцию и был максимально эффективен. В зависимости от типа нагрузки – емкостная или индуктивная – определяется и выбор ограничителя пускового тока.

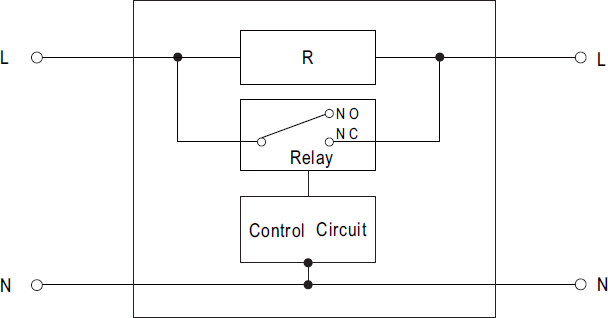

В составе ограничителя пускового тока серий ICL (в корпусе и на DIN рейку) компании MEAN WELL применяется дополнительный резистор, включающийся последовательно в цепь питания нагрузки и ограничивающий протекающий ток на определенный промежуток времени. Применение ограничителя пускового тока этого типа целесообразно только для емкостной нагрузки, так как таким способом увеличивается только время заряда входной емкости и нет влияния на работу остальных узлов.

Блок-схема ограничителя пускового тока ICL

Блок-схема ограничителя пускового тока ICL

Включение резистора производится на ограниченный промежуток времени, за время которого пусковой ток нагрузки (ток заряда входного фильтра последующего AC/DC преобразователя) снизится до значения, при котором не произойдет срабатывание автоматического выключателя («автомата»). Как определить допустимую нагрузку для самого ограничителя, то есть количество блоков питания, которые можно к нему подключить, описано здесь.

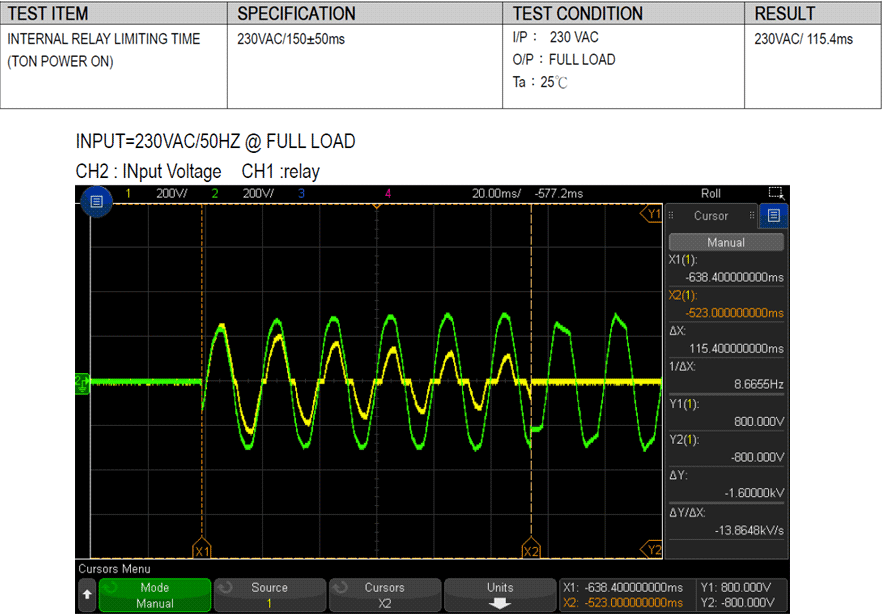

Промежуток времени, во время которого включается токоограничивающий резистор в ограничителе пускового тока, нормируется и указан в Спецификации как параметр INTERNAL RELAY LIMITING TIME. По окончании этого промежутка времени происходит шунтирование резистора контактами реле, дополнительное падение тока прекращается и он полностью потечет в нагрузку, без ограничений:

Продолжительность включения реле в ICL-28

Продолжительность включения реле в ICL-28

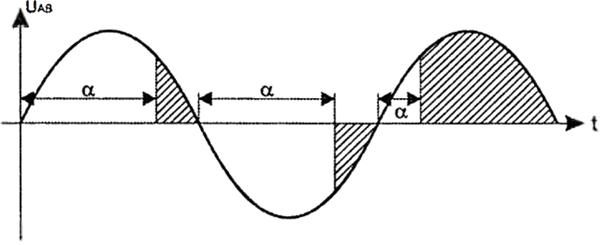

Для индуктивной нагрузки (электродвигатели, насосы и помпы на их основе) применение ограничителя пускового тока этого типа окажется полностью бесполезным, так как ограничение тока таким путем не позволит электродвигателю выйти на рабочий режим и раскрутиться на полную мощность. Для такого типа нагрузки должно применяться специальное устройство – устройство плавного пуска, которое ограничивает подачу входного напряжения на промежуток времени α, и на нагрузку подается только оставшаяся часть от полупериода синусоидального входного напряжения (на примере однофазного питания):

Принцип ограничения подачи напряжения в устройстве плавного пуска электродвигателей

Принцип ограничения подачи напряжения в устройстве плавного пуска электродвигателей

Пропорционально этому промежутку времени будет и потребление тока. В каждом полупериоде промежуток отсечения α сокращается, соответственно увеличивается подача тока, при этом двигатель, постепенно наращивая обороты, сокращает его потребление до номинального значения. Поэтому ключевой особенностью использования устройства плавного пуска является даже не ограничение пускового тока как таковое, а повышение энергоэффективности всей установки с электродвигателем, улучшения качества работы электродвигателя и повышение срока его службы.

Для консультаций или уточнения информации по источникам питания MEAN WELL можно обращаться по адресу электронной почты Meanwell@chipdip.ru.