Надежность и срок службы блоков питания MEAN WELL

В числе значимых характеристик источников питания, влияющих на принятие решения о выборе в пользу той или иной серии, являются сведения о гарантийном сроке на модель, ее надежности и сроке службы. И если гарантийный срок достаточно точно определен в Спецификации на серию источников питания от MEAN WELL, то с оценкой надежности и определением срока службы такой однозначности нет по целому ряду причин.

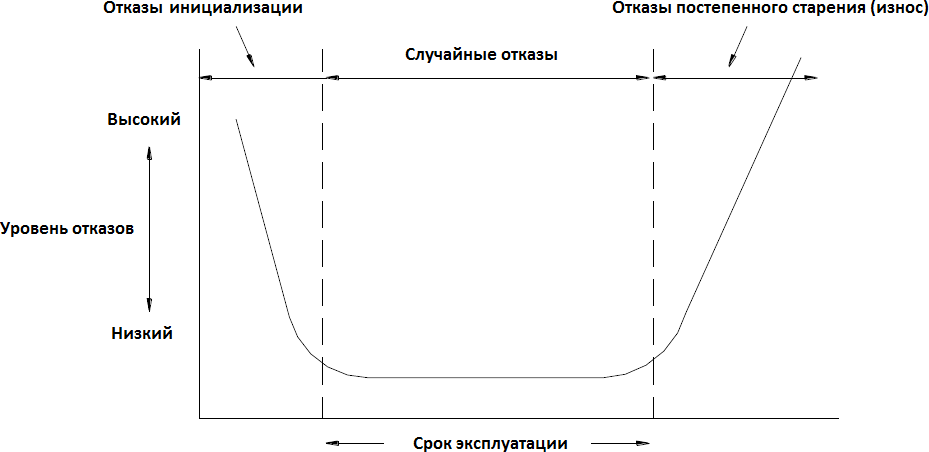

Любые электронные устройства, и источники питания в том числе, имеют неравномерный уровень отказов (Failure Rate) в течение жизненного цикла.

Уровень отказов в различные периоды эксплуатации

Уровень отказов в различные периоды эксплуатации

Наибольшее количество отказов проявляется на этапе инициализации устройства – когда происходит первое включение готового блока питания и проверка его характеристик. Минимизировать это количество отказов позволяет тщательный контроль поступающих компонентов, отлаженное производство и выборочное тестирование в партии (для ряда серий производитель проводит 100% начальное тестирование собранных блоков питания и преобразователей). Когда все начальные отказы себя уже проявили, наступает достаточно продолжительный (многолетний) период случайных отказов. На этом этапе, в силу принятых технологических решений, выбранных компонентов и топологии, отказы возможны, но их количество не превышает некий допустимый для производителя и экономически целесообразный уровень. Далее со временем физического износа и устаревания материалов и компонентов (их деградации из-за условий эксплуатации) уровень отказов с течением времени возрастает. Иными словами, на этом этапе срок службы источника питания подходит к концу.

Какие факторы больше всего влияют на надежность источника питания и его работоспособность?

- Температура. Сюда относится, как непосредственно температура окружающей среды, так и условия вентиляции блоков питания. Чем лучше обеспечены условия конвекции воздуха и чем стабильнее температура окружающей среды, тем лучше.

- Влажность и пар. Чем более высокие значения влажности, тем выше риск выхода из строя блока питания. Аналогичным образом влияют и перепады температуры среды, когда возможно образование конденсата. Поэтому при выборе источника питания целесообразно обращать на степень защиты корпуса IP (при наличии), или заливку защитным компаундом устройства частично или целиком (potted, semi-potted, указывается в Спецификации на серию).

- Пыль. Использование блока питания в запыленных условиях может привести как к непосредственному отказу компонентов в составе блока питания, например, вентилятора охлаждения, так и вызвать нарушение изоляции между отдельными узлами. Поэтому целесообразно предусматривать защиту от пыли блока питания, например за счет использования дополнительного пылевого фильтра, а также проводить периодический осмотр и чистку.

- Вибрации и ударные нагрузки. Воздействие этого фактора может привести к механическому износу компонентов и источника питания в сборе, например, могут возникнуть физические повреждения намоточных компонентов, мест паек, ослабнуть фиксация проводов в разъемах и т.д.

- Электромагнитное поле. Важно учитывать как непосредственное расположение источников сильных электрических и/или магнитных полей в области размещения источника питания, так смена направлений этих полей в процессе эксплуатации такого оборудования. Большинство блоков питания имеет целый ряд защит (в том числе от перенапряжения), но не всегда эти защиты способны в полной мере защитить сам блок питания, либо неблагоприятные электромагнитные условия могут существенно сократить его срок службы.

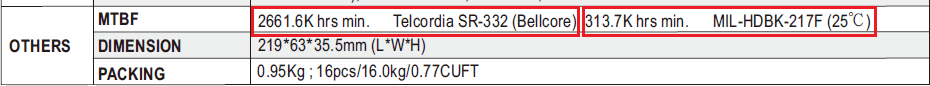

Основной характеристикой определяющей надежность источников питания компании MEAN WELL является средняя наработка на отказ (Mean Time Before Failure, MTBF), выражаемый в часах эксплуатации, на примере блоков питания серии ELG-150.

Средняя наработка на отказ в Спецификации

Средняя наработка на отказ в Спецификации

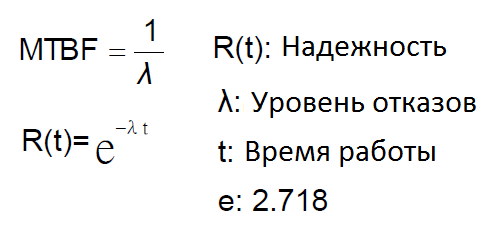

Средняя наработка на отказ ожидаемое значение, предназначенное для прогнозирования надежности. Наработка на отказ – это среднее время работы до тех пор, пока надежность изделия не снизится до 36.8%. Например, если наработка на отказ продукта составляет 20 000 часов, это не означает, что этот продукт может использоваться в течение 20 000 часов, а скорее, что после использования в течение 20 000 часов вероятность его работы составляет 36.8% (e-1 = 0.368). Непосредственно средняя наработка на отказ и вероятность правильной работы (надежность) связаны между собой соотношениями:

Средняя наработка на отказ и надежность

Средняя наработка на отказ и надежность

Средняя наработка на отказ (MTBF) может быть рассчитана с помощью двух различных методик: по расчетам по компонентам и стресс-тестирование. Для расчета наработки на отказ компания MEAN WELL обычно использует два стандарта – MIL-HDBK-217F и TELCORDIA SR/TR-332 (Bellcore).

Непосредственно срок службы источников питания компания MEAN WELL не нормирует и не указывает в Спецификации, так как это значение полностью зависит от условий эксплуатации, представленных выше. В упрощенном виде, срок службы устройства определяется на основе зависимости срока службы его компонентов от температуры окружающей среды и уровня нагрузки. Поэтому для каждого устройства определяется наиболее критичный компонент и производится расчет срока службы, исходя из срока службы этого компонента в различных условиях. Например, из Отчета тестирования для EDR-120-24 таким компонентом является электролитический конденсатор в одной из цепей:

Расчетный срок службы наиболее критичного компонента для EDR-120-24

Расчетный срок службы наиболее критичного компонента для EDR-120-24

В ряде случаев также в отчете тестирования указывается ожидаемый срок службы, полученный на основе ускоренного тестирования (Accelerated Life Test), на примере того же EDR-120-24 он составляет порядка 50 тыс. часов, что составляет порядка 5 с половиной лет в режиме работы 24/7/365. Но это скорее оценочный, чем фактический, срок.

По вопросам, связанным с выбором и использованием продукции компании MEAN WELL, следует обращаться по адресу электронной почты Meanwell@chipdip.ru.