Плюсы наличия корректора коэффициента мощности в продукции MEAN WELL

Одним из существенных факторов при выборе источника питания является наличие корректора коэффициента мощности (ККМ), или power factor correction (PFC) в англ. обозначении. Коэффициент мощности характеризует собой качество потребления энергии из сети электропитания переменного тока, и, чем ниже значение коэффициента мощности, тем хуже качество потребления.

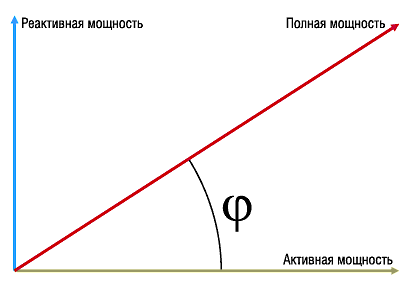

Как известно из курса электротехники, полная мощность в цепи переменного тока определяется как вектор между активной мощностью и реактивной:

Соотношение мощности в цепи переменного тока

Соотношение мощности в цепи переменного тока

Коэффициент мощности это косинус угла между активной мощностью (нижним катетом) и полной мощностью (гипотенузой) – чем острее этот угол, тем выше значение косинуса ϕ и тем меньше реактивная мощность. Существует несколько разных способов уменьшения реактивной мощности, например, использование специальных фильтров, симметрирующих различную нагрузку, чтобы минимизировать или исключить сдвиг фаз между напряжением и протекающим током. Такой подход является пассивным способом коррекции коэффициента мощности.

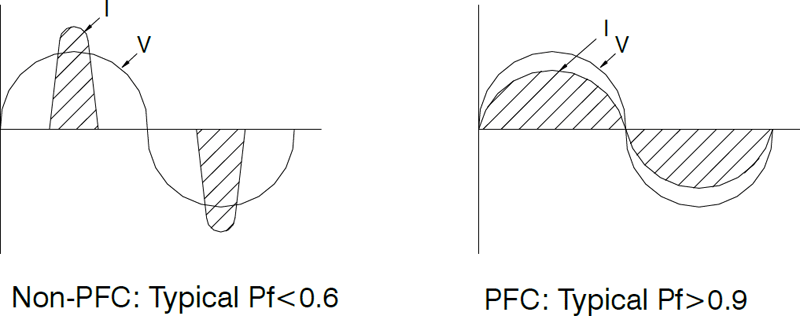

Для импульсных источников питания надежным и хорошо себя зарекомендовавшим стал способ использования активной коррекции коэффициента мощности – за счет использования силовых полупроводников, которые обеспечивают протекание тока синхронно (в одной фазе) с изменением напряжения сети электропитания. В этом случае, нагрузка ведет себя практически как резистивная и потери на реактивную мощность минимальны.

Влияние корректора коэффициента мощности на форму тока

Влияние корректора коэффициента мощности на форму тока

В зависимости от мощности источника питания, его назначения и эффективности в ряде серий источников питания MEAN WELL применяются различные способы коррекции коэффициента мощности. Наибольшее распространение получили активные корректоры коэффициента мощности из одной или двух стадий. Сравнительные особенности представлены в таблице:

| Топология ККМ | Преимущества | Недостатки | Ограничения |

|---|---|---|---|

| Одна стадия |

|

|

|

| Две стадии |

|

|

|

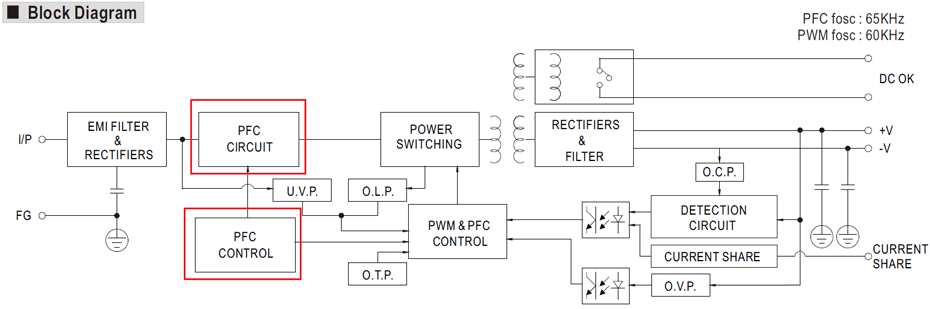

Как устроен корректор коэффициента мощности из двух стадий лучше всего проиллюстрировать на примере блок диаграммы импульсного источника питания на DIN рейку серии SDR-960:

Корректор коэффициента мощности две стадии на примере SDR-960

Корректор коэффициента мощности две стадии на примере SDR-960

Для двух стадий характерна связь корректора коэффициента мощности (PFC) с драйвером управления ШИМ контроллером силовых полупроводников (выделено красным), что позволяет оптимизировать потребление тока из сети электропитания с током потребления нагрузки на выходе источника питания. Корректор коэффициента мощности из двух стадий чаще всего встречается в блоках питания средней и большой мощности высокой эффективности.

Таким образом, можно выделить следующие плюсы наличия корректора коэффициента мощности в импульсных источниках питания:

- Нагрузка в цепи электропитания максимально приближена к резистивной, то есть происходит наиболее полное потребление электроэнергии с минимальными потерями мощности. Иными словами, на выделяемую мощность подключения можно «подвесить» больше потребителей электроэнергии и получить ее более эффективное использование (повысить энергоэффективность).

- В трехфазной сети электропитания, при активной нагрузке токи, протекающие в линиях, совпадают по фазе с напряжением фазы, поэтому не возникает перекоса суммы обратных токов в нейтрали, соответственно, не возникает в ней перегрева, и минимизируется опасность «отгорания нуля».

- Улучшается электромагнитная совместимость различных устройств, включенных в сеть электропитания. При активной нагрузке, гармонические составляющие протекающего тока значительно меньше, чем в цепях со сдвигом фаз между напряжением и током, плюс форма протекающего тока максимально приближена к гармонической, поэтому возникает меньше помех в сети электропитания, и требуется меньше дополнительных мер по фильтрации входного напряжения.

Минус у наличия ККМ только один – поскольку это дополнительный узел в схеме источника питания, то, соответственно, стоимость блока питания (в общем случае) несколько выше, чем без ККМ при прочих равных условиях. Но эта разница не перевешивает те выгоды, которые обеспечиваются за счет наличия корректора коэффициента мощности в источнике питания.

Принимая во внимание эти плюсы, компания MEAN WELL в большинство импульсных источников питания своего производства включает корректор коэффициента мощности – серии RSP, HRP, UHP, MSP. Полная подборка импульсных источников питания с корректором коэффициента мощности корпусного типа представлена на нашем сайте.

Для консультирования или уточнения информации по источникам питания MEAN WELL обращайтесь по адресу электронной почты Meanwell@chipdip.ru.